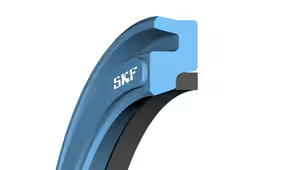

All profiles listed here are SKF standard machined K1012 piston seals and can be produced in virtually any dimension and in different materials.

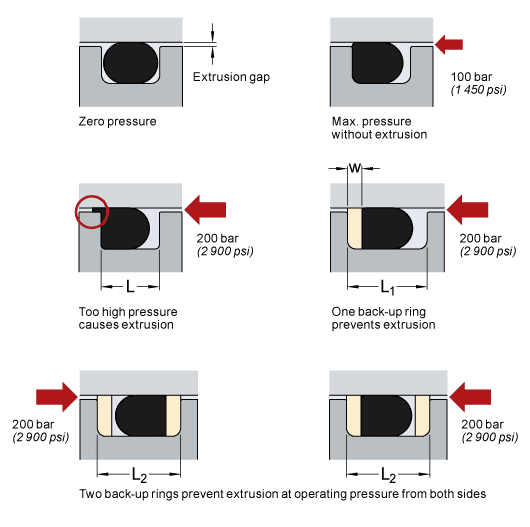

K1012 piston seals are single-acting chevron seal sets designed to seal pressurized space against the atmosphere or – in case of back-to-back arrangement with intermediate guide ring – to seal between two pressurized spaces, mainly for reciprocating movements.

These seals are part of the comprehensive SKF machined seals assortment and the design is based on applications in standard hydraulic systems with conventional hydraulic oils. The operating parameters are as defined in the sealing and material data sheet. Requirements deviating from these parameters can be met to a certain degree by changing the geometry in the SKF SEAL JET machine software.

Application range

- Reciprocating pistons in hydraulic cylinders; small swivelling motion also permissible

- Especially for heavy hydraulic applications or heavy-duty operating conditions

- For repair of heavy machinery respectively for worn running surfaces, when re-tightening is possible

Materials

Material selection has a significant impact on the seal performance as well as reliability of the whole system.

Recommended sealing materials and operating parameters are defined in the seal data sheet. SKF Ecotal/ECOPUR/SKF Ecotal is the recommended standard material combination for the seal.

The support ring material is mainly selected based on the diameter (SKF Ecotal available up to 400 mm). Please consider moisture swelling when using SKF Ecomid. Support rings made of rubber allow an increased axial compensation of housing tolerances but could result in less stability.

For special requirements on service temperature and media compatibility up to a certain extent, various ECOPUR polyurethane materials are available.

For increased chemical and thermal resistance, we recommend SKF Ecorubber materials, but attention should be paid to limitations in wear and pressure resistance.

The pressure ring material is mainly selected based on the diameter (SKF Ecotal available up to 400 mm). Please consider moisture swelling when using SKF Ecomid. Pressure rings made of hard polyurethane offer easier installation but could result in higher friction at high pressure level.

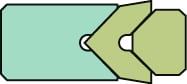

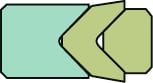

Available seal versions

There are different versions of the K1012 seals with specific features available (please find more detailed information in the related detailed profile descriptions and seal data sheets linked below).

| K1012-M | K1012-T |

|  |