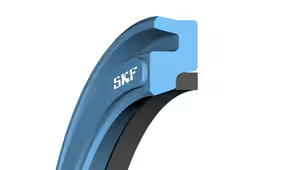

MD-L seals are double-acting piston seals (fig. 1) and have a nitrile rubber (NBR) sealing ring with thermoplastic polyester elastomer (TPC) anti-extrusion rings on both sides, which incorporate the polyacetal (POM) guide rings. The guide and anti-extrusion rings are split for easy installation. MD-L profiles are suitable for pressures up to 250 bar (3 625 psi) in medium duty applications and are available in metric sizes. Some sizes fit seal housings in accordance with ISO 6547:1981. For additional information, refer to MD-L profile data below.

| |

| Material codes | Sealing ring: N80/047 Guide rings: POM/076 Support rings: TPC-ET72/075 |

| Pressure | Up to 250 bar (3 625 psi) |

| Speed | Up to 1 m/s (3.2 ft/s) |

| Temperature range |  For temperature limits depending on fluid compatibility → see Engineering information |

| Extreme low temperature range: may be intermittently exposed (e.g. cold start-up) without seal damage, but seal performance may be compromised while in this range |

| Temperatures below the recommended operating range: seal performance depends on system design |

| Recommended operating temperature range for this profile and material |

| Temperatures above the recommended operating range: acceptable only with reduced pressure and/or speed |

| Extreme high temperature range: only occasional short-term exposure (e.g. cylinder in curing oven of a powder coating process) |

| Dimension standards | Some sizes fit seal housings in accordance with ISO 6547:1981. |

| Counter-surface | → see Engineering information |

| Size list | → Metric |

| Additional information | → Piston seals with integrated guide rings |

| Maximum values of application parameters (e.g. pressure, speed, temperature) should not be applied continuously nor simultaneously. | |