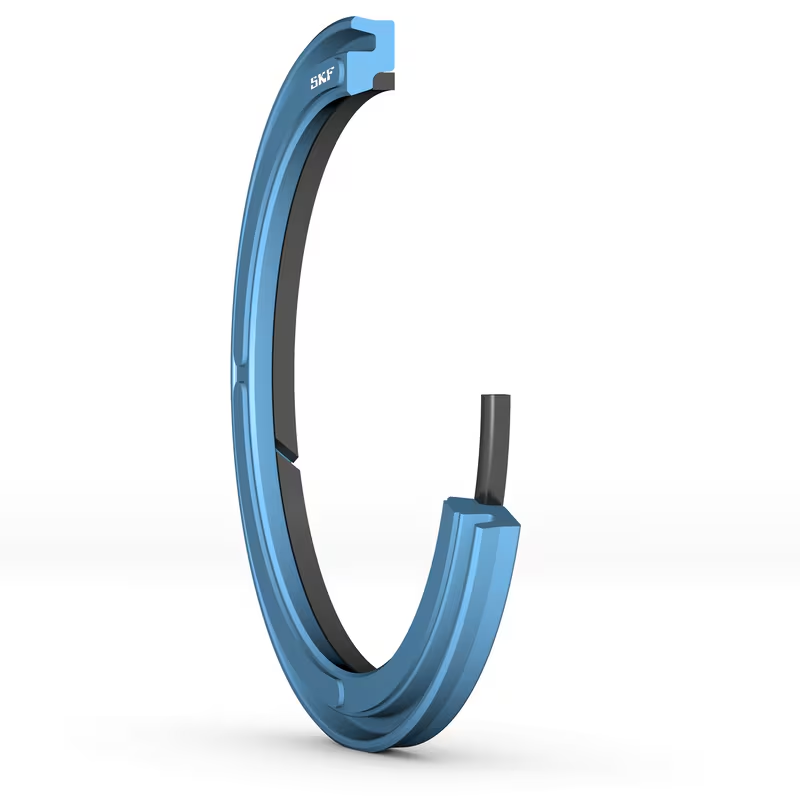

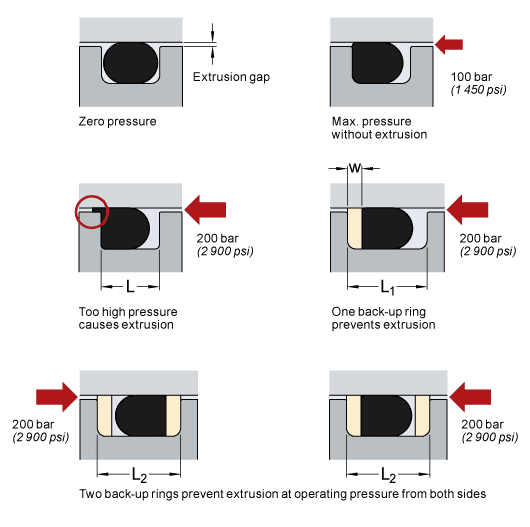

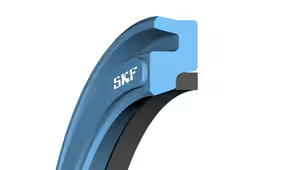

RBB seals are polyurethane U-cup buffer seals and (fig. 1) have a LUBRITHANE (TPU) sealing ring that incorporates a polyamide (PA) or polyacetal (POM) anti-extrusion ring. The flexible outside static sealing lip and notches in the front face safeguard that pressure can return to the system side of the buffer and prevent build-up of pressure between the rod and buffer seals. These profiles are suitable for extreme pressure peaks and demanding workloads in heavy duty applications up to 690 bar (10 000 psi). They are available in metric and inch sizes, some metric sizes fit seal housings in accordance with ISO 7425-2:1989.

| |

| Material codes | Sealing ring: Metric sizes → U-1029Inch sizes → U-1023 Anti-extrusion ring: Metric sizes → P-2518Inch sizes → 707→ see Engineering information |

| Pressure | Up to 690 bar (10 000 psi) |

| Speed | Up to 1 m/s (3.2 ft/s) |

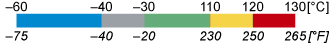

| Temperature range |  |

| Extreme low temperature range: may be intermittently exposed (e.g. cold start-up) without seal damage, but seal performance may be compromised while in this range |

| Temperatures below the recommended operating range: seal performance depends on system design (precision guiding arrangement recommended) |

| Recommended operating temperature range for this profile and material |

| Temperatures above the recommended operating range: acceptable only with reduced pressure and/or speed |

| Extreme high temperature range: only occasional short-term exposure (e.g. cylinder in curing oven of a powder coating process) |

| Dimension standards | Some metric sizes fit seal housings in accordance with ISO 7425-2:1989. |

| Counter-surface | → see Engineering information |

| Size list | → Metric |

| Maximum values of application parameters (e.g. pressure, speed, temperature, e-gap) should not be applied continuously nor simultaneously. | |