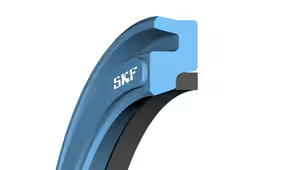

All profiles listed here are SKF standard machined S03 rod seals and can be produced in virtually any dimension and in different materials.

S03 rod seals are asymmetric, single-acting, loaded – either via O-ring or helicoil springs – lip seals designed to seal pressurized space against the atmosphere, mainly for reciprocating movements.

These seals are part of the comprehensive SKF machined seals assortment and the design is based on applications in aggressive media or with high thermal demands. The operating parameters are as defined in the sealing and material data sheet. Requirements deviating from these parameters can be met to a certain degree by changing the geometry in the SKF SEAL JET machine software.

Application range

- Reciprocating and swivelling rods in cylinders, push rods, fittings

- Fittings in chemical industry – valid for S03-F, S03-S and S03-SX

- As rod seal for shifting functions (e.g. clutch operation) – valid for S03-P

- As rod seal for clamping functions – valid for S03-P

- When appropriate preload element is used, also suitable for low temperatures (down to -50 °C) – valid for S03-P

Materials

Material selection has a significant impact on the seal performance as well as reliability of the whole system.

You can see the recommended standard material combinations for the different S03 designs in the table below.

| Design | S03-F | S03-P | S03-S | S03-SX |

| Sealing element | SKF Ecoflon 3 | ECOPUR | SKF Ecoflon 3 | SKF Ecoflon 3 |

| Energizer / spring | FKM 75 | NBR 70 | 1.4310 | 1.4310 |

For specific application related requirements, various thermoplastic materials are available.

For special requirements on service temperature and media compatibility up to a certain extent, various polyurethane materials are available.

For decreased leakage rates we recommend S03-P with ECOPUR polyurethane materials, but attention should be paid to limitation in gliding speed.

For higher gliding speeds, we recommend S03-F with thermoplastic materials, but attention should be paid to limitations in installation behaviour and leak tightness.

Alternative materials for the energizer (such as NBR, FKM, MVQ, EPDM, H-NBR, etc.) are used for special requirements on service temperature and media compatibility.

Available seal versions

There are different versions of the S03 seals with specific features available (please find more detailed information in the related detailed profile descriptions and seal data sheets linked below).

| S03-F | S03-P | S03-S | S03-SX |

|  |  |  |