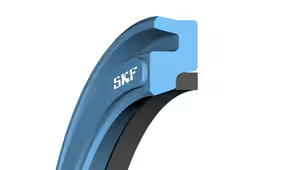

S1S seals are polyurethane U-cup rod seals and (fig. 1) are made of ECOPUR (TPU) and have a single-lip design. The geometry has been optimized using FEA (Finite Element Analysis) to provide the longest possible service without maintenance. They are suitable for pressures up to 400 bar (5 800 psi) in medium to heavy duty applications and are available in metric sizes. Some fit seal housings in accordance with ISO 5597:2010. For additional information, refer to S1S profile data and the S1S test results below.

FILTERS

- Rod diameter

- Housing groove diameter

- Housing groove width

- Pressure limit, maximum

- Product designation

- Design

- Primary sealing element

- Unit system

Reset all

2367 results

Display in:MetricImperial

Sort by:

Relevance

1

2

3

4

5

6

7

8

9

10

| |

| Material codes | ECOPUR |

| Pressure | Up to 400 bar (5 800 psi) |

| Speed | Up to 1 m/s (3.2 ft/s) |

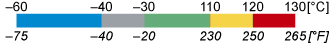

| Temperature range |  |

| Extreme low temperature range: may be intermittently exposed (e.g. cold start-up) without seal damage, but seal performance may be compromised while in this range |

| Temperatures below the recommended operating range: seal performance depends on system design (precision guiding arrangement recommended) |

| Recommended operating temperature range for this profile and material |

| Temperatures above the recommended operating range: acceptable only with reduced pressure, speed, e-gap and/or with the use of a full-face anti-extrusion ring |

| Extreme high temperature range: only occasional short-term exposure (e.g. cylinder in curing oven of a powder coating process) |

| Dimension standards | Some sizes fit seal housings in accordance with ISO 5597:2010. |

| Counter-surface | → see Engineering information |

| Size list | → Metric |

| Additional information | → Polyurethane U-cup rod seals |

| Maximum values of application parameters (e.g. pressure, speed, temperature, e-gap) should not be applied continuously nor simultaneously. | |

S1S Test results

To verify that the S1S rod seal meets the intended functionality requirements and to validate its performance against similar competitive products, multiple benchmark tests were performed under medium duty and heavy-duty conditions.

The results of the verification testing are shown here with respect to leakage, seal extrusion length and friction force. In all three critical parameters for seal performance, the SKF S1S rod seal performed as good as or better than the competitor seals.

Additionally, the test results showed that the preload loss on the outer diameter as well as the lip cross section (which is a combination of compression set and seal wear) were excellent.

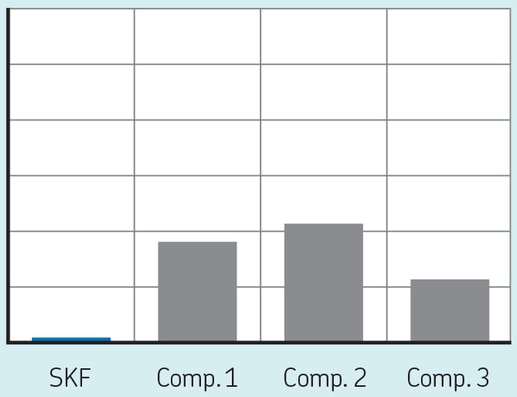

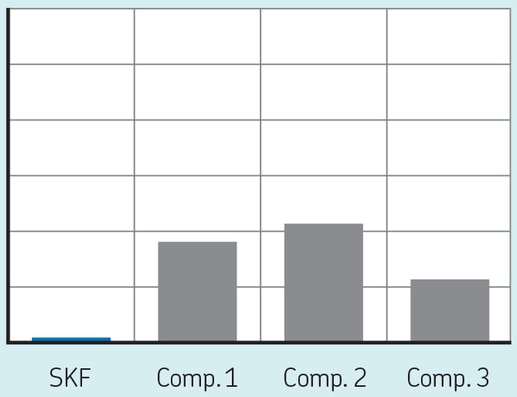

Leakage

The S1S rod seal performed best in terms of overall leakage. Competitor 3 is second, but therefore shows drawbacks in terms of friction force and, as a result of this, an increased extrusion length.

The S1S rod seal performed best in terms of overall leakage. Competitor 3 is second, but therefore shows drawbacks in terms of friction force and, as a result of this, an increased extrusion length.

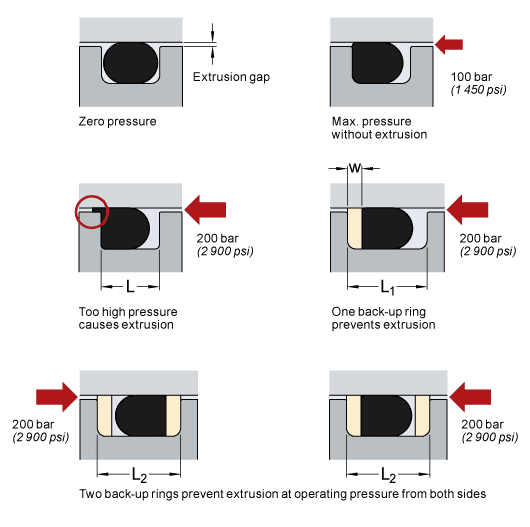

Extrusion length

The extrusion performance is a strong indicator for the material performance. The S1S rod seal is again showing excellent test results, whereas competition 2 and 3 are already showing increased extrusion length.

The extrusion performance is a strong indicator for the material performance. The S1S rod seal is again showing excellent test results, whereas competition 2 and 3 are already showing increased extrusion length.

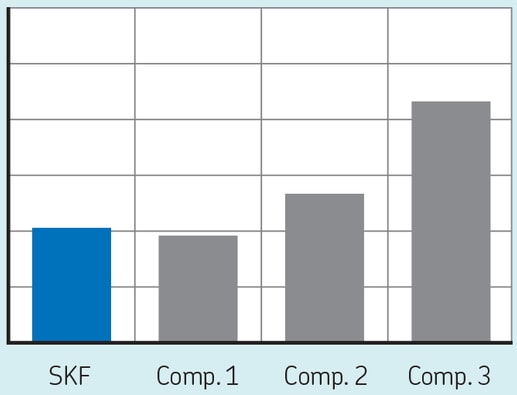

Friction force

The S1S rod seal is working on a comparably low friction level in combination with a superior leakage performance, whereas competitor seal 1 already requires a certain leakage to achieve a very similar frictional behaviour. Competitor rod seals 2 and 3 showed increased frictional forces caused by the extrusion length, which again loads the sealing material with higher temperatures.

The S1S rod seal is working on a comparably low friction level in combination with a superior leakage performance, whereas competitor seal 1 already requires a certain leakage to achieve a very similar frictional behaviour. Competitor rod seals 2 and 3 showed increased frictional forces caused by the extrusion length, which again loads the sealing material with higher temperatures.